![]()

Contents: Basics; Other Sources; Is It RFI, Or A Ground Loop?; Data Bus Systems; Sound Systems; Navigation Systems; Persistent Problems; Vehicles From Hades; Don't Give Up!;

There are two types of RFI; devices you interfere with when transmitting, and devices which interfere with your ability to receive. Both require similar techniques, but what works in one case doesn’t necessarily work for the other. The device being interfered with is called the victim. RFI caused by current from an external source is called ingress. RFI caused by internal signals being radiated is called egress. (See the ARRL’s RFI Book for a complete treatment of RFI and techniques for dealing with it.)

Vehicles are adding more computer-controlled devices with each new model. It is not uncommon for vehicles to have four or more high-speed Body-Chassis Area Networks (B-CANs) connecting various subsystems together. For example, a B-CAN allows wheel speed sensors to share data with anti-lock braking and stability systems. Unfortunately, digital signals often radiate RF and are very difficult to suppress. Efforts to do so can interfere with the network operation.

Like home Ethernet networks, RFI from B-CANs manifest themselves as evenly-spaced birdies across the HF spectrum. A transceiver with auto notch filtering can become necessary. Modern infotainment systems require audio amplifiers to be connected to power at all times. Due in part to their high gain, even small amounts of RF ingress can cause havoc. Efforts to control common mode using ferrite cores are essential in minimizing this form of RFI. Ferrite snap-on cores can be of great help with both RF ingress and egress, but factory vehicle wiring seldom allows enough slack in the harness to install multiple-turn cores. This requires multiple snap-on cores if there is enough wire length available.

Note: Wiring harnesses containing B-CANs should never be choked or bypassed to ground with capacitors.

Radio Frequency Interference (RFI) is the major bane of every mobile operator. The most common offender is the spark ignition system all gas engines currently use, and it sounds like this. The level of ignition RFI is directly related to the age (increasing spark gap due to wear) of the spark plugs, and heat deterioration of the plug wires if used. It can be minimized with proper bonding, but in severe cases, replacement of the plugs (and wires) may be the only recourse. On the forefront are laser ignition systems. It remains to be seen if any RFI is generated by these systems. They will undoubtedly use some form of PWM (Pulse Width Modulation), and are potentially a future RFI generator.

For some reason, power cabling is often blamed for RFI issues. Pundits often recommend twisting the power cable so it looks like a cork screw. That doesn't work, but it very well may ruin the cable! The rational is, that CAT5 cable is twisted. True, but that is done to prevent cross talk between the pairs, not for RFI reduction. The real cause is covered in the Ground Loop section. Incidentally, installing ferrite split beads on a power cable in an effort to cure RFI is technically unfounded.

There are a few things that don't work very well for RFI problems, yet enjoy a large audience. One of those is the brute force filter. They're often advertised as a cure for alternator whine, common mode current, as well as RFI imposed on the power wiring (an exceedingly rare occurrence). For alternator whine, they're a patch at best, and if you wire your installation correctly, you won't need one. One thing brute force filters will do, is increase voltage drop. For no other reason, they should be shunned. The rule of thumb is, if they cured a problem, then something else in the installation is amiss!

There is another type of RFI we have to deal with as well, and that is when our operation interferes with that of the vehicle we're operating from. The most prevalent cause is common mode current. This occurs when RF energy flows on the outside of the coax shield and/or over the motor leads. The problem is exacerbated by abbreviated mounting methods (clip, lip, glass, clamp, and post mounts as examples), with trailer hitch mounting as the worst offender of all. All of these mounting methods increase ground losses (which are already too high!).

There is another type of RFI we have to deal with as well, and that is when our operation interferes with that of the vehicle we're operating from. The most prevalent cause is common mode current. This occurs when RF energy flows on the outside of the coax shield and/or over the motor leads. The problem is exacerbated by abbreviated mounting methods (clip, lip, glass, clamp, and post mounts as examples), with trailer hitch mounting as the worst offender of all. All of these mounting methods increase ground losses (which are already too high!).

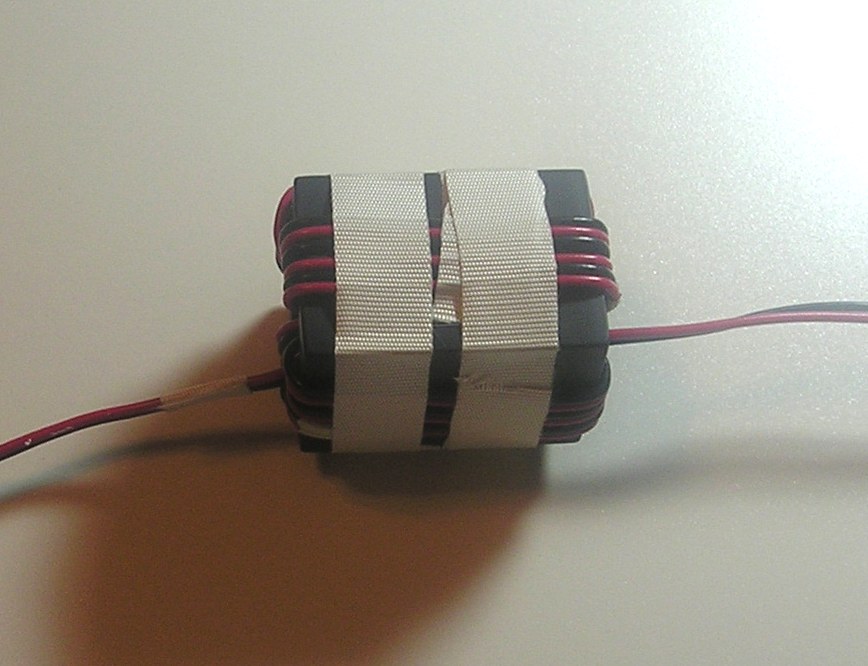

The photos left and right photos depict a properly wound, common mode chokes for the feed line and motor leads respectively. Both utilize a 3/4" ID, mix 31, split bead. When you place a ferrite split bead over a wire, it looks electrically like a resistor in series with an inductor. Like any inductor, the amount of inductance (efficacy) is to the square of the number of turns.

Every late-model transceiver has two specific built-in features; a noise blanker, and some form of DSP (digital signal processing). The implementation is different between makes of course, but the derived benefits are basically the same; reduced perceived noise. For the most part they work well for the intended purpose. However, relying on them to remove excessive RFI, especially ignition RFI, has major drawbacks, not the least of which is reduced receiver performance. Therefore, it is always best to reduce the offending RFI as much as possible, rather than relying on the NB and DSP to do it for you.

Remember too, the detection of RFI is a square law function. So a small effort in reducing the RFI at the source, makes a big change in the perceived level of RFI.

Almost every new model now comes standard with LED headlights, or at least as an option. The LEDs are pulse-width modulated (PWM) to limit current draw to a specific level. However the PWM is accomplished, the wave form is square, and they generate harmonics. So far, it appears that OEM versions are almost RFI clean. The same can't be said for after-market units, however.

High Intensity Discharge (HID) lighting systems are also very popular. Similar to LED lighting control systems, they use square-wave inverters to generate the high voltage needed to generate the arc. While most factory-installed systems are mostly RFI free, many aftermarket systems are not so tame RFI wise. Caveat Emptor.

LED and HID lighting aren't the only devices installed in a vehicle controlled with PWM. Electrically powered radiator cooling fans, power steering, and water pumps (both brushed and brushless) are switching over to PWM. They use less current overall, their speed control is more precise, and when used along with motorized radiator slats, no cooling system thermostat is needed. All of these devices are being used to minimize parasitic losses. Read that as increased fuel mileage.

In case you've forgotten, the "D" in LED stands for diode, and diodes do a great job of detecting RF. When they do, the resulting voltage is often fed back into the vehicle's wiring. This usually doesn't cause problems, but it can. Remembering that antennas are mounted on the rear, and most CHMSLs (Center High Mounted Stop Light) are LED, enough voltage can be imposed to cause an RFI issue. If you think you have a problem caused by RF rectification by LEDs, have someone watch the various LED lights (CHMSL especially), for any flickering while you talk. If they do, split beads are about you're only recourse.

As mentioned in the Antenna Mounting article, mounting antennas on hatches and tailgates which have defroster wires, are a major source of RFI for several reasons. Since the hatches and tailgates are not RF grounded, any common mode current flowing on the coax feed line can be induced into the vehicle's wiring with predictable results. This issue (common mode) is exacerbated by clip mounts. Further, clip mounts typically locate the antenna very close to the rear window of most sedans. Therefore, the much higher amount of radiated RF will be coupled into the defroster wires with the same results—high levels of RFI.

Navigation systems are becoming more common too. Both older models (florescent back-lit), and newer models (LED edge and back-lit) can cause RFI, again due to rapid on-off switching. Typically the RFI is localized, and only cause problems when transceiver heads are mounted close to them.

Original equipment alternators are getting larger (amperage wise), and more sophisticated too. Modern regulators use both PWM and PPM (pulse position modulation) to control both voltage and current. Although the regulators themselves don't cause alternator whine, they do add to the level of RFI generated under the hood.

It should be noted that most alternator diodes are more than just a diode. It is not uncommon for them to be designed to break down—zener by another name—if the reverse voltage exceed ≈18 volts. This is done as a means of reducing voltage spikes expressed of the vehicle's wiring, should a load-dump transient (LDT) occur. An LTD is usually caused by a loose battery connection—yet another reason to properly maintain your vehicle's battery connections.

AEB (Automatic Emergency Braking) systems are rapidly becoming ubiquitous, as are the SIDAR, LIDAR & RADAR systems which support it. All of these subsystems rely on computer control for activation. While the individual modules don't normally emit RFI, they are interconnected by data buses (B-CANs), which can produce RFI birdies throughout the HF spectrum. This is also true of APA (Automatic Parking Assist) and ASC (Automatic Stability Control) systems, which use the same sensors the AEB uses.

Some older Automatic Braking Systems (ABS), and cam shaft position devices use a reluctance (coil-magnet) type sensor. Their the output wave form is very peaky (non-sinusoidal), so they tend to generate a buzzing sound which varies with the speed of the vehicle and/or the engine. Later units use Hall devices, and are virtually RFI free.

As alluded to in the last paragraph, it is just as important to know the things which do not cause RFI, but are often blamed. One of those is the air conditioning clutch. While there may be a back EMF spike when they're disengaged, they are in fact a stationary electromagnet, and do not have RFI-causing brushes.

By definition, a ground loop is a voltage differential between any two points. Ground loops often manifest themselves as an RFI problem. Almost without exception, ground loops are caused by incorrect wiring practices. Because their severity is affected by the amount of current drawn, they're typically seen (or heard) only when transmitting. However, they can affect receive too, especially when a mag mount antenna is used.

The best cure is not to cause ground loops in the first place by correctly wiring your gear. This includes the over-zealous use of ground straps. For example, unlike commercial radio equipment, the power cable ground lead in amateur radio equipment is usually connected directly to the chassis. From a purely technical standpoint, no other grounding is necessary. Yet, manufacturers often recommend grounding the chassis to prevent electrical shocks (?), TVI, BCI, and other problems (from Icoms' owners manuals). Here is something to consider: If grounding the chassis cured or reduced an RFI problem, then something else in the installation is amiss!

Modern vehicles are awash with computerization. Some models have as many as 130 CPUs, with more coming with every new model. Since they need to talk to one another, the most economical way is via a data bus system—not unlike an Ethernet hookup. The Digital Electronics article covers this subject in more detail, but it is important to restate the obvious.

Digital signals are by definition, square waves with very fast rise times. Attempting to choke off the harmonics they generate, tends to round off the the leading corners of the square wave. This high frequency distortion, or rolloff, causes timing delays in the data bus. About the only course of action is to properly mount your antenna, and install a common mode chokes on the coax and motor leads (if used) to minimize RF leakage.

Some vehicle computer systems use a color burst crystal as an oscillator (3.579545 MHz). The 41st harmonic is 146.76134 MHz, which causes problems with the 146.16/76 repeater pair. However, component tolerances can cause the harmonic to be anyplace between about 146.70 MHz, to as high as 146.80 MHz.

Nowadays, even inexpensive (if you could call them that) vehicles come factory-equipped with premium sound systems. Upgraded models often have Bluetooth®, Sync®, MP3®, and cellphones built in. As a result, most audio power amplifiers are wired hot. That is to say, they're on anytime the ignition is on, and in some cases when it is not. Adding some insult, the wiring for these devices are spread throughout the vehicle to speakers, antennas, and interconnections. Finding the entry point for RF is both tedious and frustrating.

Capacitive bypassing of the various components isn't recommended, which leaves split beads as the only alternative, and a good one at that. However, using them may require adding length to the wiring harnesses. While time consuming, it is usually worth the effort. It is best to apply the beads as close to the offended device as possible. For example, placing beads at the speaker ends of the wiring harness don't work as well as installing them close to the power amplifier. This is also true of auxiliary inputs (Sync®, MP3®, etc.). Remember too, it is best to use multiple turns on one bead than one turn on multiple beads.

What was said above about ground loops, is doubly true about sound system RFI. Proper wiring, common mode chokes, and proper antenna mounting are the best prevention measures, and will out-weigh any cure you could ever apply.

Based on current trends, every vehicle sold in America will soon have a navigation system (Navi) as standard equipment. For the most part, the requisite antenna is placed at the rear of the vehicle's roof. This puts them in close proximity to our mobile antennas. Thankfully, very little RFI is encountered if the rest of the installation was done correctly. This said, if you're using a video adapter to display your transceiver's digital readout, you may indeed encounter an RFI problem.

Based on current trends, every vehicle sold in America will soon have a navigation system (Navi) as standard equipment. For the most part, the requisite antenna is placed at the rear of the vehicle's roof. This puts them in close proximity to our mobile antennas. Thankfully, very little RFI is encountered if the rest of the installation was done correctly. This said, if you're using a video adapter to display your transceiver's digital readout, you may indeed encounter an RFI problem.

Currently, the only mobile transceiver with composite video out, is the Icom IC-7000, and the standard is either NTSC or PAL depending on the model. This output can then be fed directly to the Navi (some models), or to an adapter like the TVandNav2Go®. Because the video level is just one volt PEP, very little RF is needed to disrupt the display.

If an adapter is used, it is best to power it from the same source the Navi is powered from to prevent a ground loop. Higher end units (≈$300USD) come equipped with the correct harness, but most lower end units (≈$150USD) don't. The latter requires great care in wiring, and proper fusing is a must! For most folks, a RigRunner® is a better alternative, however the power cable to the adapter should be beaded. Further, the video cable from the transceiver to the Navi or adapter should be beaded at both ends! Four or five turns through a mix 31 split bead is usually enough.

If an adapter is used, it is best to power it from the same source the Navi is powered from to prevent a ground loop. Higher end units (≈$300USD) come equipped with the correct harness, but most lower end units (≈$150USD) don't. The latter requires great care in wiring, and proper fusing is a must! For most folks, a RigRunner® is a better alternative, however the power cable to the adapter should be beaded. Further, the video cable from the transceiver to the Navi or adapter should be beaded at both ends! Four or five turns through a mix 31 split bead is usually enough.

No matter how hard you try, there are some RFI issues which defy suppression. One of those is vehicle data bus systems. Honda for example, uses at least three in most of their vehicles. These data buses carry information between the various on-board computer systems. Since they're digital, their signals tend to be rich in harmonics, which often extend well into the HF spectrum. Because they operate on different frequencies, they easily mix resulting in birdies every few kHz. They're usually not much more than a nuisance, as their interference level is typically low. However, the better you RFI-proof your vehicle, the poorer the band conditions are, the worse the apparent S+N/N ratio (SNR) will be.

Since these data buses are running throughout the vehicle, split beads are of little help, especially if you don't know which on-board device generates the bus in the first place. This is where a Service Manual is of great help. Even then, it is difficult at best to reduce, much less eliminate, the birdies. The only recourse is to use the built in DSP most late-model amateur transceivers feature.

There's one problem which might be assumed to be caused by RFI, and that's engine hunting (stumbling, uneven idling, misfires, etc.). While RFI can indeed cause it, varying loads on the alternator can also be a cause especially if you run high power. One way to tell is to listen to the alternator when someone else is on the radio. If the mechanical whine from the alternator varies with the load, you're discovered the cause. If it doesn't change, it is probably RFI ingress to the control systems.

Some vehicles just can't be quieted down, no matter what you do. Even vehicles which are otherwise identical, can have different levels of RFI. They're sort of the lemons of the amateur mobile world. If someone ever figures out why this is so, they'll become over-night millionaires!

Hybrids, especially those from Toyota, are some of the RFI noisiest vehicles money can buy (as are plug-in vehicles). There are just too many digital signals to deal with, along with all of those of a standard vehicle when the engine is running. John Pavelich, VE3XKD, has spent untold hours of labor, and a wad of hard-earned cash getting his Prius quiet enough for HF work. Few amateurs possess John's, seemingly unending patience, to take on such a formidable task!

Hybrids and plug-ins aren't the only ones either. Some of the newer common-rail diesel engines emit enough RFI to drown out the best of signals. Listen to this one! Yes, you could use split beads on the offending injectors, if you could get to them! In most cases, they're hidden under the intake manifold and/or under sound insulating covers. This negates the use of split beads, even if you could get to the harness to apply them.

If possible, before buying any vehicle, take along a portable AM radio. Tune off a station, and listen to the background noise level. Then start the vehicle. If the background level comes way up, check other similar vehicles on the dealer's lot to see what they do. While subjective, you'll at least have a feel for what you're up against. Fact is, ones as bad as the MP3 example above, can be clearly heard.

Just about any vehicle can be quieted down if you have enough time, patience, and funds for the beads etc. Here's a few tips about going about the task.

Install your radio gear, antenna, wiring, bonding etc. first, following the recommendations herein. Once you're done, then (and only then) assess what extra work needs to be done. If you just throw the radio in the vehicle, and stick on the antenna like it was a piece of duck tape, you're going to get a false impression of the real level of RFI.